⚡

Power Line Monitoring Solution

Autonomous UAV-Based Transmission Line Inspection & Defect Detection

95%+

Detection Accuracy

80%

Time Reduction

24/7

Autonomous Operation

<5s

Defect Detection

Решење

RAVAM – A New Era of Predictive Maintenance

End-to-End Solution

RAVAM offers a comprehensive AI-powered solution for automated VLS monitoring, from data acquisition to actionable insights.

Advanced Technology

Our proprietary sensor fusion and AI-driven analytics detect defects with unprecedented accuracy and speed.

Real-Time Monitoring

Get a comprehensive, near real-time view of your entire network with automated defect detection and reporting.

Data Acquisition → AI Analysis → Actionable Insights.

How It Works:

The RAVAM 3-Step Process

1. Data Acquisition

High-resolution aerial imagery (AFS) with resolution up to 2 cm/pixel for pole-by-pole inspection

LiDAR data for precise 3D terrain modeling

Precision GNSS for sub-10cm accuracy using PPK method

Automated data ingestion into unified storage

2. AI Analysis

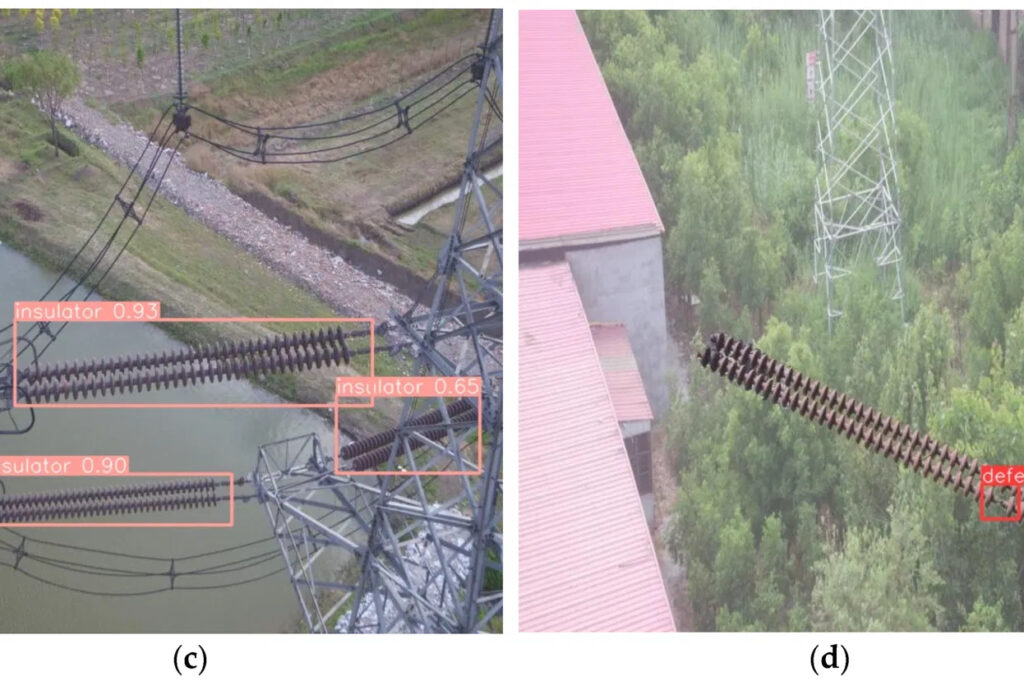

Automated defect recognition on VLS support structures

Detection of violations within VLS protection zones

Identification of vegetation encroachment (trees over 4m)

Analysis of wire sag, clearance, and insulator condition

3. Actionable Insights

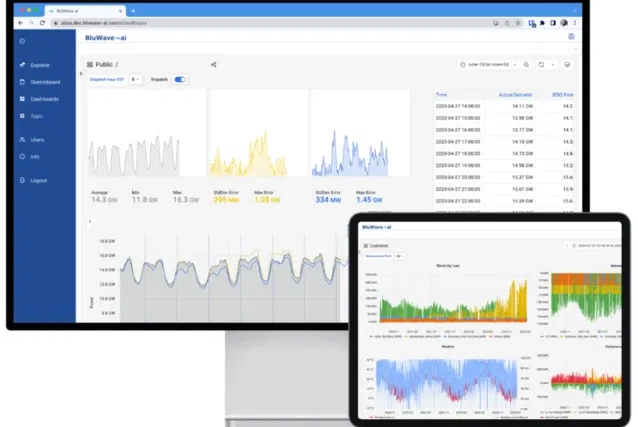

Interactive cartographic interface for data visualization

Automated generation of structured reports (CSV, XLSX, DOCX, KML)

Pole-by-pole inspection records with defect statements

Prioritized maintenance recommendations

Key Capabilities

🔍

Multi-Sensor Inspection

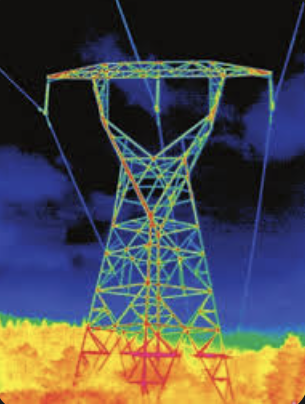

RGB cameras (50MP), thermal imaging (-40°C to +550°C), LiDAR (±2cm accuracy) for comprehensive line assessment.

🧠

AI Defect Detection

Computer vision models trained on 100,000+ defect images for automatic classification of corrosion, breaks, and hotspots.

📡

Real-Time Monitoring

Live data streaming with instant alerts for critical defects, ensuring rapid response to emergencies.

🔍

3Д мапирање

Generate detailed 3D models of your entire network with resolution requirements of 5cm/pixel for general analysis and 2cm/pixel for pole-by-pole inspection.

🔮

Predictive Maintenance

Machine learning models forecast equipment failures weeks in advance based on thermal and visual trend analysis.

📡

Automated Reporting

Generate detailed inspection reports with GPS coordinates, defect classifications, and priority recommendations.

Технолошки стек

РАВАМ пружа свеобухватна решења за праћење инфраструктуре и аутономно истраживање, покретана напредном вештачком интелигенцијом и фузијом више сензора.

🛸 UAV Platforms

- Multi-rotor drones for detailed inspections (45min flight time)

- Fixed-wing drones for long-distance corridors (520min range)

- Hybrid VTOL for combined versatility (180min flight)

- Autonomous navigation with obstacle avoidance

- Weather-resistant design (15 m/s wind tolerance

📷 Sensor Suite

- 50MP RGB cameras with 30x optical zoom

- Thermal imaging: 640×512 resolution, ±2°C accuracy

- LiDAR: 300,000 points/sec, ±2cm accuracy, 200m range

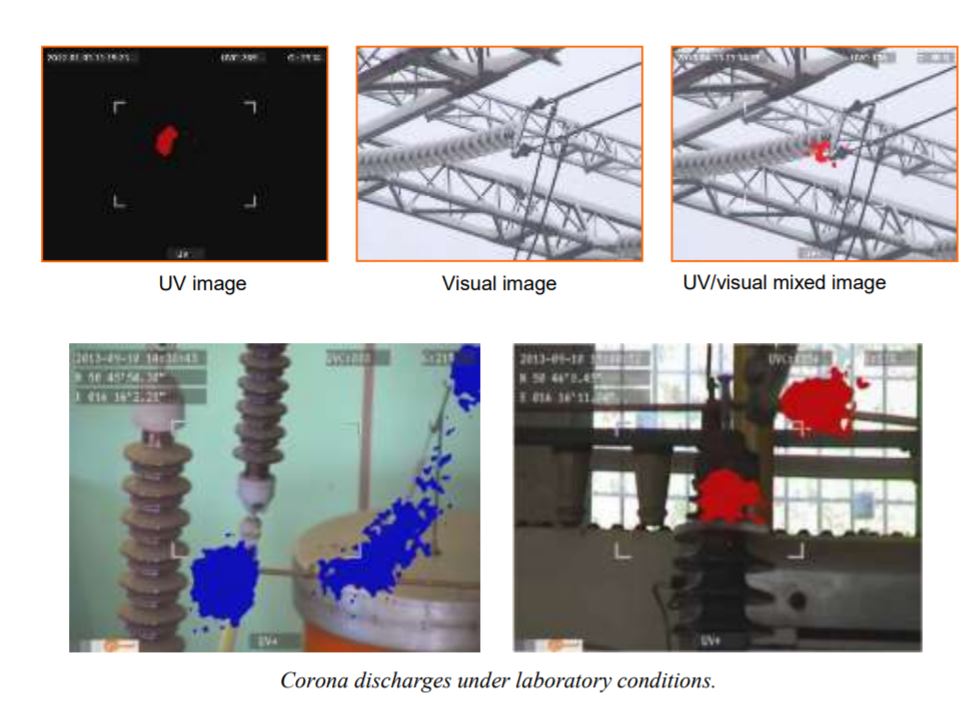

- Corona discharge (UV) detection cameras

- RTK-GPS for ±1cm positioning accuracy

🧠 AI & Analytics

- Deep learning models for defect classification

- Thermal anomaly detection (<5 sec processing)

- Conductor sag measurement and analysis

- Vegetation encroachment mapping

- Predictive failure modeling (weeks advance warning)

☁️ Data Platform

- Cloud-based data storage and processing

- Real-time dashboard with live alerts

- Historical trend analysis and comparison

- API integration with existing SCADA systems

- Automated report generation (PDF/Excel)

Benefits

Benefits

💰 Cost Reduction

Reduce inspection costs by 60-70% compared to traditional helicopter or manual inspections. Minimize downtime with predictive maintenance.

⚡ Reliability Enhancement

Identify defects before they cause outages. Continuous monitoring prevents cascading failures and ensures grid stability.

🛡️ Safety Improvement

Eliminate worker exposure to high-voltage equipment and dangerous heights. Zero accidents during inspection operations.

📈 Data-Driven Decisions

Access comprehensive historical data for asset management, capital planning, and regulatory compliance reporting.

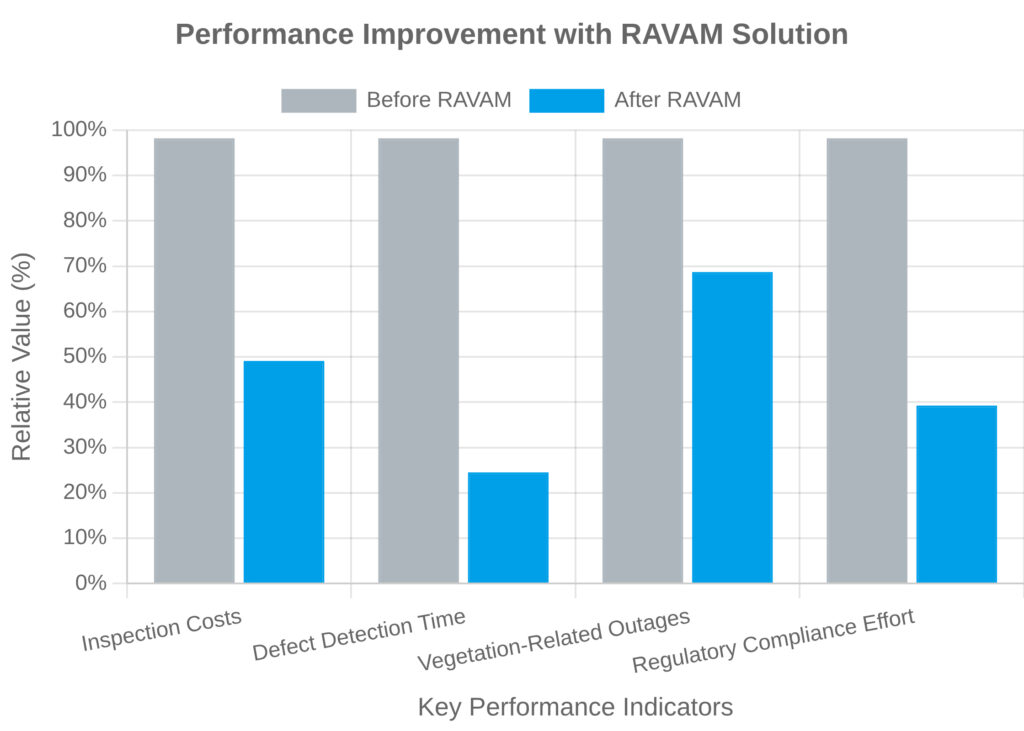

Real-World Results

Transforming Grid Management: Expected Outcomes.

“By implementing AI-powered inspection systems, power companies have seen a significant reduction in technological disruptions due to undetected defects, with some reporting up to 40% fewer outages in the first year alone.”

— Industry Analysis Report, 2024

50% Reduction in Inspection Costs

Automated UAV data collection and AI analysis significantly reduces labor hours and equipment costs compared to traditional manual inspections.

75% Faster Defect Detection

Our AI processes inspection data in hours rather than days or weeks, allowing for rapid identification and prioritization of critical issues.

30% Reduction in Vegetation-Related Outages

Precise identification of vegetation encroachment enables proactive maintenance before trees can damage power lines or cause outages.

100% Regulatory Compliance

Comprehensive documentation and standardized reporting ensure full compliance with regulatory requirements for VLS inspection and maintenance.

The Proposal: A Phased Approach

A Partnership for the Future

Phase 1: Pilot Program (3-6 months)

Scope:

50 km of your critical 110kV and 220kV lines, focusing on areas with high vegetation density and historical maintenance challenges.

Deliverables:

Complete data acquisition using UAVs

AI-powered defect detection and analysis

Interactive cartographic interface setup

Comprehensive reports and defect statements

Objectives:

Demonstrate solution effectiveness

Validate accuracy of AI detection

Calculate ROI based on pilot results

Train your team on the platform

Phase 2: Full-Scale Deployment (12-18 months)

Scope:

Rollout across your entire VLS network, with prioritization based on criticality and maintenance history.

Deliverables:

Complete system integration with existing GIS

Customized reporting templates

Automated defect detection for all VLS assets

Ongoing support and maintenance

Objectives:

Achieve full operational efficiency

Implement predictive maintenance capabilities

Reduce inspection costs by up to 50%

Ensure 100% regulatory compliance

01

Schedule a Demo

Experience our platform in action with a personalized demonstration of the RAVAM solution.

02

Define Pilot Scope

Together, we’ll identify 100km of your most critical 110kV and 220kV lines for the initial pilot.

03

Finalize Partnership

Complete the partnership agreement and begin implementation of the RAVAM solution.

Use Cases

Hotspot Detection

Thermal imaging identifies overheating connectors, insulators, and transformers before failure occurs.

AI Defect Detection

High-resolution RGB imaging detects rust, corrosion, and material degradation on towers and conductors.

Vegetation Management

LiDAR mapping measures clearance distances and identifies encroaching trees requiring trimming.

Multi-Sensor Inspection

Detect cracked, broken, or contaminated insulators that could cause flashovers or outages.

Conductor Sag Analysis

Monitor conductor clearance heights and sag variations to ensure safety and compliance.

Corona Discharge Detection

UV cameras identify corona discharge indicating insulation breakdown or high-voltage issues.

Ready to Transform Your Power Grid Monitoring?

Schedule a demo to see our autonomous inspection platform in action.