Empowering Success Together

Revolutionizing Power Grid Reliability:

An AI-Powered Solution for Automated VLS Monitoring

The Challenge:

The High Cost of Traditional Inspection

The Hidden Costs of an Aging Grid.

Dangerous & Inefficient: Manual inspections put workers at risk and are time-consuming, requiring specialized equipment and extensive safety protocols.

Human Error & Missed Defects: Manual post- processing of UAV data is highly susceptible to human error, leading to missed defects and increased technological disruptions.

Vegetation Management: Identifying vegetation encroachment manually is labor-intensive, yet trees exceeding 4m in height under power lines pose significant risks.

Complex Compliance: Meeting regulatory requirements for VLS inspection demands extensive documentation and consistent reporting formats.

The Solution:

RAVAM – A New Era of Predictive Maintenance

From Reactive to Predictive: The Future of Grid Management.

End-to-End Solution

RAVAM offers a comprehensive AI-powered solution for automated VLS monitoring, from data acquisition to actionable insights.

Advanced Technology

Our proprietary sensor fusion and AI-driven analytics detect defects with unprecedented accuracy and speed.

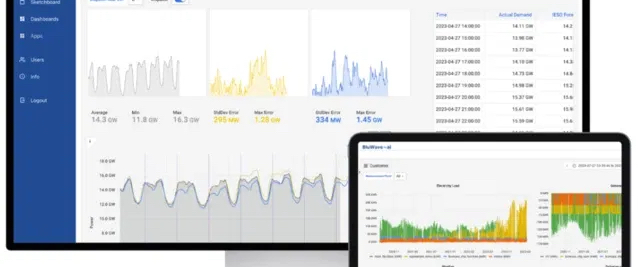

Real-Time Monitoring

Get a comprehensive, near real-time view of your entire network with automated defect detection and reporting.

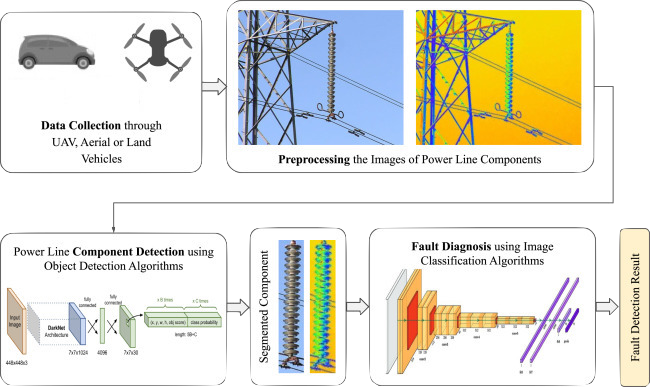

How It Works:

The RAVAM 3-Step Process

Data Acquisition → AI Analysis → Actionable Insights.

1. Data Acquisition

High-resolution aerial imagery (AFS) with resolution up to 2 cm/pixel for pole-by-pole inspection

LiDAR data for precise 3D terrain modeling

Precision GNSS for sub-10cm accuracy using PPK method

Automated data ingestion into unified storage

2. AI Analysis

Automated defect recognition on VLS support structures

Detection of violations within VLS protection zones

Identification of vegetation encroachment (trees over 4m)

Analysis of wire sag, clearance, and insulator condition

3. Actionable Insights

Interactive cartographic interface for data visualization

Automated generation of structured reports (CSV, XLSX, DOCX, KML)

Pole-by-pole inspection records with defect statements

Prioritized maintenance recommendations

Key Benefit: Eliminate human error and reduce inspection time by up to 75% while improving defect detection accuracy.

Key Features & Capabilities

Unparalleled Accuracy and Detail.

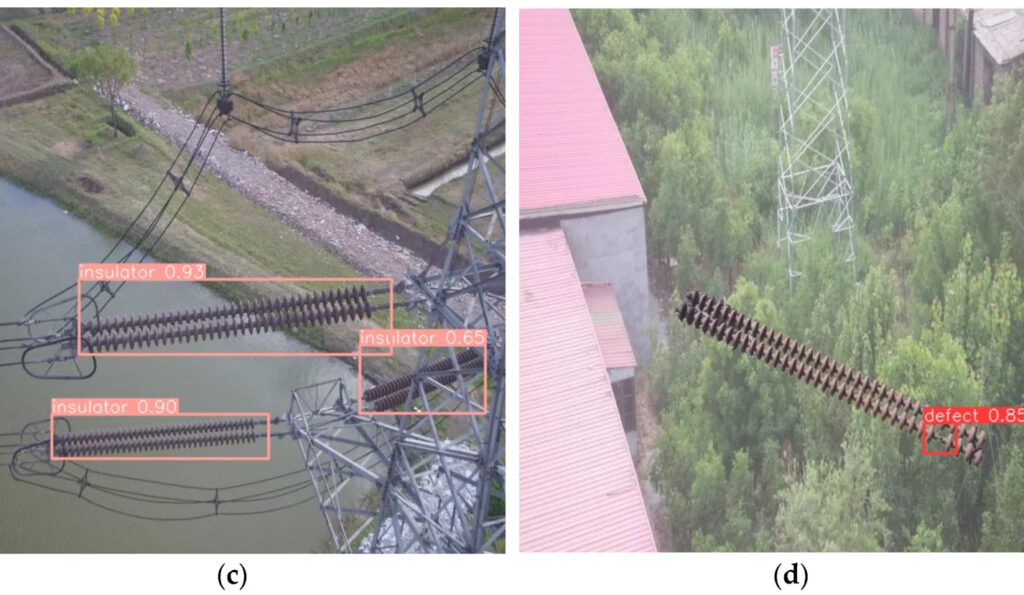

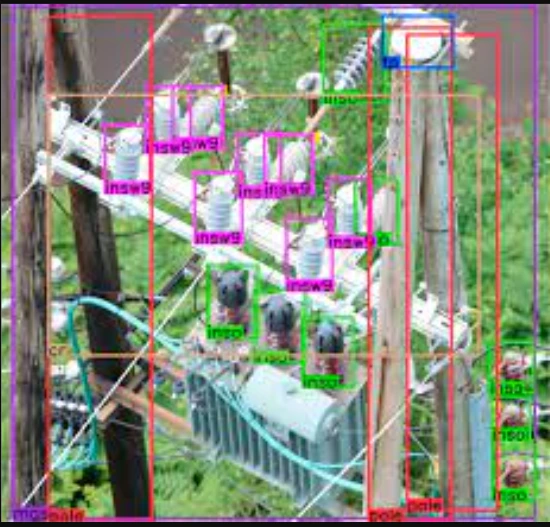

Comprehensive Defect Detection

Our AI algorithms detect a wide range of defects including support structure issues, wire damage, insulation problems, and vegetation encroachment with precision accuracy.

High-Resolution 3D Modeling

Generate detailed 3D models of your entire network with resolution requirements of 5cm/pixel for general analysis and 2cm/pixel for pole-by-pole inspection.

Predictive Analytics

Identify potential failures before they happen with our advanced analytics that track changes over time and provide early warnings of developing issues.

Automated Reporting & Integration

Pole-by-pole inspection records and defect statements

Vegetation content maps for VLS clearings

OGC-compliant standards (WMS/WMTS, WCS, WFS)

Multiple data formats (CSV, XLSX, DOCX, KML)

FSTEC 239 secure software development standards

Advanced Defect Detection

AI-Powered

AI-Powered Defect Recognition

Our AI algorithms automatically identify defects and violations across all VLS components with precision and consistency that surpasses manual inspection.

Support Structure Defects

✧ Inclination of supports beyond permissible norms

✧ Missing components (angles, bolts) on metal supports

Wire & Cable Issues

✧ Wire damage, fraying, or breakage

✧ Improper sag and clearance distances

Insulation Problems

✧ Damaged or contaminated insulators

Vegetation & Protection Zone

✧ Trees exceeding 4m in height under power lines

✧ Unauthorized structures within protection zones.

Experience, Expertise, and a Shared Vision

The RAVAM Advantage

01

Proven Technology

Our AI models are trained on thousands of hours of real-world power line inspection data, achieving detection accuracy rates that exceed manual inspection methods.

02

Deep Industry Expertise

Our team brings over 80 years of combined experience in AI, UAV systems, and energy infrastructure, ensuring solutions that address real-world challenges.

03

Collaborative Approach

We work closely with your team to tailor our solution to your specific network requirements, ensuring seamless integration with existing systems and workflows.

04

Future-Proof Platform

Our service-oriented architecture is scalable and adaptable, with OGC-compliant interfaces ensuring easy integration with your existing GIS and asset management systems.

05

Our Commitment:

We deliver a solution that meets all technical requirements while ensuring data security, compliance with ISO/IEC 27001:2022 standards, and full intellectual property rights transfer.

06

Continuous Innovation

We are committed to ongoing research and development, ensuring our solution evolves with the latest advancements in AI and UAV technology to keep your operations at the forefront of efficiency and safety.

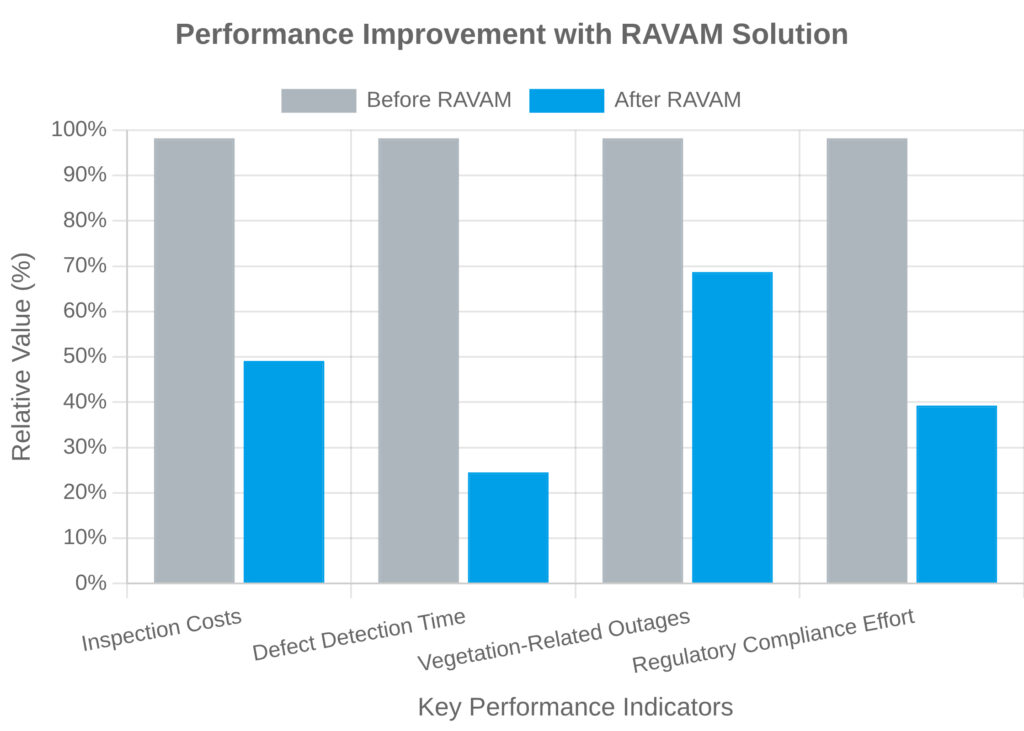

Real-World Results

Transforming Grid Management: Expected Outcomes.

“By implementing AI-powered inspection systems, power companies have seen a significant reduction in technological disruptions due to undetected defects, with some reporting up to 40% fewer outages in the first year alone.”

— Industry Analysis Report, 2024

50% Reduction in Inspection Costs

Automated UAV data collection and AI analysis significantly reduces labor hours and equipment costs compared to traditional manual inspections.

75% Faster Defect Detection

Our AI processes inspection data in hours rather than days or weeks, allowing for rapid identification and prioritization of critical issues.

30% Reduction in Vegetation-Related Outages

Precise identification of vegetation encroachment enables proactive maintenance before trees can damage power lines or cause outages.

100% Regulatory Compliance

Comprehensive documentation and standardized reporting ensure full compliance with regulatory requirements for VLS inspection and maintenance.

The Proposal: A Phased Approach

A Partnership for the Future

Phase 1: Pilot Program (3-6 months)

🔎 Scope:

50 km of your critical 110kV and 220kV lines, focusing on areas with high vegetation density and historical maintenance challenges.

🛒 Deliverables:

Complete data acquisition using UAVs

AI-powered defect detection and analysis

Interactive cartographic interface setup

Comprehensive reports and defect statements

📌 Objectives:

Demonstrate solution effectiveness

Validate accuracy of AI detection

Calculate ROI based on pilot results

Train your team on the platform

Phase 2: Full-Scale Deployment (12-18 months)

🔎 Scope:

Rollout across your entire VLS network, with prioritization based on criticality and maintenance history.

🛒 Deliverables:

Complete system integration with existing GIS

Customized reporting templates

Automated defect detection for all VLS assets

Ongoing support and maintenance

📌 Objectives:

Achieve full operational efficiency

Implement predictive maintenance capabilities

Reduce inspection costs by up to 50%

Ensure 100% regulatory compliance

Implementation Guarantee:

Our solution will be fully compliant with all requirements specified in the technical request document, including software registry compliance and data security standards.

Next Steps & Contact

Let’s Build the Future of Energy, Together!

Ready to transform your power line inspection process? Here’s how we can get started:

01

Schedule a Demo

Experience our platform in action with a personalized demonstration of the RAVAM solution.

02

Define Pilot Scope

Together, we’ll identify 100km of your most critical 110kV and 220kV lines for the initial pilot.

03

Finalize Partnership

Complete the partnership agreement and begin implementation of the RAVAM solution.

Request a Consultation!

Click here to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Experience, Expertise, and a Shared Vision

Case study

01

Excessive sag of the power lines.

Impact:

Reduced ground clearance, increasing the risk of contact with objects or people below.

Increased stress on tower structures and insulators, potentially leading to long-term fatigue and failure.

The lines may fall out of compliance with regulatory safety standards for clearance.

Solution:

Autonomous drone fleet performs scheduled LiDAR and photogrammetry missions, creating precise 3D models to quantify sag with centimeter accuracy. This data, integrated via the Ravam.co platform, automatically flags sag exceeding design parameters by approximately 12%, generating prioritized work orders for maintenance crews to conduct tensioning or reconductoring, thereby mitigating the risk to public safety and infrastructure.

02

Structural failure of the utility pole, causing it to lean and the power lines to sag.

Impact:

Extreme danger to maintenance crew due to an unstable structure and potentially live,

sagging lines.

High risk of electrocution or injury for anyone in the vicinity.

Extensive damage to infrastructure, requiring complex and hazardous repair or replacement.

Solution:

Drones conduct close-proximity visual and thermal inspections from a safe standoff distance, identifying critical structural defects like wood rot, base cracking, or hardware failure without exposing personnel to the unstable asset. The data provides engineers with a detailed damage assessment to plan a safe, precise reconstruction operation, drastically reducing crew exposure to hazardous conditions.

03

A heavy tree branch has fallen onto the power lines.

Impact:

Imminent line failure due to the extreme weight and tension.

High risk of electrocution or injury for maintenance crew due to the unstable branch and

stressed lines.

Power outage and extensive damage to the lines and pole structure.

Solution:

Autonomous drones provide immediate emergency situational awareness, safely assessing the branch’s position, conductor stress, and potential collateral damage. High-resolution imagery and LiDAR data enable remote diagnosis and planning for a controlled removal operation, allowing crews to approach the site with full knowledge of the hazards and the exact equipment required, minimizing their time in the danger zone.

04

Severe ice and snow accumulation on power lines.

Impact:

Catastrophic failure of lines or tower due to extreme weight and tension.

Widespread power outage.

Extreme safety hazard for maintenance crew due to the unstable structure and dangerous

weather conditions.

Solution:

Drones, equipped for all-weather operation, perform critical damage assessment flights in conditions too hazardous for ground crews. Using specialized sensors and LiDAR, they accurately measure ice accretion thickness, map the extent of the event, and identify structures at imminent risk of failure. This real-time data is streamed to the command center, enabling utilities to prioritize de-icing efforts, allocate resources efficiently, and keep personnel safe until controlled mitigation or emergency response can be executed.

05

Tree branches in close proximity.

Impact:

Arcing and short circuits.

Power outages.

Physical damage to lines.

Fire hazard.

Solution:

Autonomous drone fleet executes precision vegetation management missions, using high-resolution imagery and LiDAR to create detailed 3D models of the clearance between conductors and surrounding foliage. The platform’s analytics automatically identify and classify vegetation incursions, generating predictive trim plans and work orders long before branches reach a dangerous proximity. This proactive, data-driven approach transforms vegetation management from a reactive cost center into a predictable, efficient program that prevents outages and mitigates fire risk.

06

Active construction with heavy machinery.

Impact:

Accidental contact with live lines.

Equipment damage.

Worker injury or electrocution.

Solution:

Drone platform provides a critical pre-work and continuous monitoring solution. Prior to construction commencement, drones conduct automated flights to map the worksite, precisely measuring and geo-tagging the location and height of all power lines. This data is used to establish and communicate exact no-go zones and safe working distances to crews. During active construction, scheduled autonomous monitoring flights can detect machinery operating in pre-defined exclusion zones in real-time, sending immediate alerts to both the construction foreman and utility safety officers to prevent an incident before it occurs.

07

Severe vegetation overgrowth (vines) on the pole and lines

08

Power lines routed through a densely forested area.

09

A faulty electrical connection or component, indicated by a severe hot spot on

the thermal image.

10

A severe thermal hot spot at the base of the tower, indicating a failing or

overloaded ground connection.

11

Severe weather, including lightning and high winds.

12

The inadequate clearance between trees and the power lines is the root cause.

13

Cause: A severe ice storm, causing heavy ice accumulation on the power lines and pole.

15

The bare branches of the tree are in close proximity to the power lines.